Introducing Outlast & our first designs

March 31, 2025

Almost exactly a year ago, with my daughter only 4 months old, our washing machine stopped working. With the pile of unwashed laundry growing as rapidly as our blood pressure, we called a repair man. He told us that, although the machine was mechanically sound (only the electronics had failed), it would be cheaper to replace the whole thing.

This struck me as insane, but it turns out that this is now the norm. An insatiable hunger for ever-increasing profit margins and aggressive pricing has steadily eroded the quality and repairability of the average home appliance, reducing their lifespan to under a decade. In other words, home appliances today are essentially disposable. As a result we create over a million tonnes of home appliance waste in the UK alone.

This experience begged the question: would it be possible to create home appliances that would last a lifetime? Could home appliances become heirlooms? If we achieve this in a way that’s commercially viable we could make a real dent in that mountain of home appliance waste, and empower people to build a richer relationship with the objects they own.

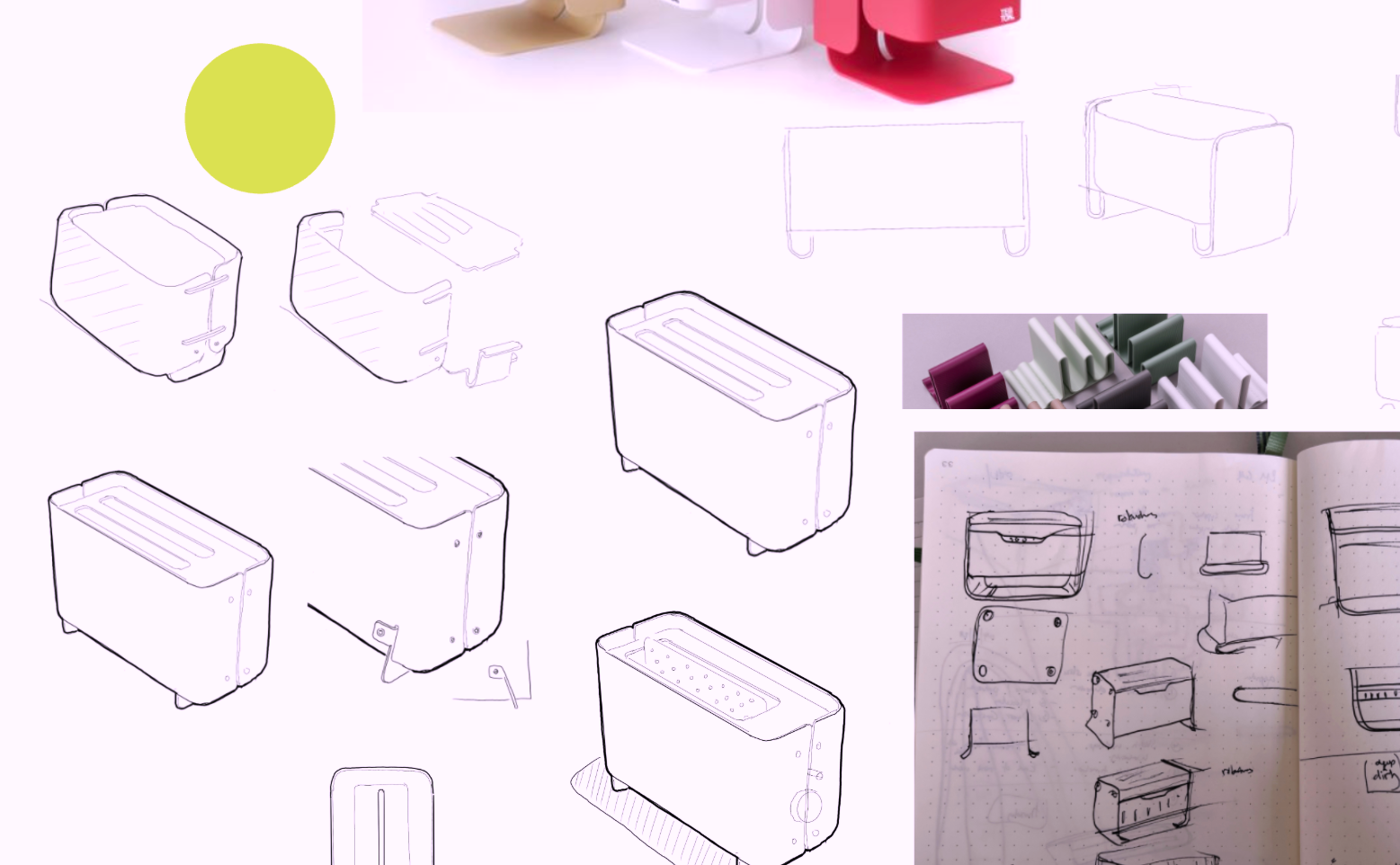

It made sense to start with a small, widespread appliance and grow from there. And so the 100 Year Toaster project was born. I teamed up with product designer Dan and his team at manufactured.design, and longtime creative collaborator Neil Simpson. Together we stripped down a bunch of broken toasters and found that, whether expensive or cheap, under their clothes most are the same - made in the same factories, using the lowest-cost techniques and materials possible, and as such hostile to repair. I went deep with the grassroots repair movement, speaking with key figures and getting their insights into the broken toasters they see in their repair cafes, and their wishlist for an ideal toaster. And most importantly, I spoke to as many regular people as I could about their toasters, what they like, love and hate about them.

And then we got to work. Since last summer we’ve had our heads down developing initial designs, which we’re excited to share today, under the new name Outlast. The goal is to get your feedback and input ahead of our next iteration.

There are a number of core qualities we wanted the designs to achieve.

1. Repairable

This was top of our list. In almost all modern toasters the key functional components - control, lift, heating and timer - are integrated by design. This makes them cheap to produce, but very fragile - if just one component fails then the whole product stops working. And even if it were possible to repair, many toasters are almost impossible to get into, with cases often glued or tabbing together rather than using screws.

So we’ve rethought the whole interior architecture of our toaster to be modular. The casing is easy to get into, and each functional component is separate and replaceable. But we want to go further - to make it repairable at home without any specialist tools, and in many cases no tools at all. We’re talking to component manufacturers about ways we can achieve “no tool repair” for the most frequently-replaced components, and we will build in features to encourage safe disassembly.

2. Easy to clean

This modularity allows us to add some other important features, like making it easier to clean. Since they’re sealed boxes, most toasters are traps for old bits of food. In fact, a build up of crumbs and grease is to blame for many toasters stopping working. When we tore down a bunch of broken toasters we bought from eBay, most contained a disconcerting volume of carbonised gunk. So we want to make the messiest parts of our toaster - like the top plate and crumb tray - removable and dishwasher safe.

3. Flexible aesthetics

For most people we spoke to, since it’s always on display, how a toaster looks is a major factor in deciding which they buy. Moving house or a new kitchen is what drives many people to replace perfectly good small appliances, to fit the new design scheme. So, if we’re serious about making a toaster that will last a lifetime, it needs to be possible to update its colour and finish. To that end, our design employs two identical sheet steel “shells” and control dials that can easily be replaced by hand. Exploring the visual design options that presents should be a lot of fun!

4. Future-proof supply chain

All of the above is irrelevant if, in 5 years, you can’t get the parts you need to keep your toaster running. So building the right supply chain is as important as designing the right product. Our goal is to keep production as local as possible, using parts that can either be fabricated in non-specialist facilities or are readily available.

We’ve still a long way to go - although we've prototyped key elements of these designs, we need to add another level of detail to make them manufacturable, finalise suppliers, test out working prototypes and get the first batch made. But we feel good about the direction we're heading in, and we're excited to get your reactions to help us stay on the right track. If you’d like to stay abreast of developments just sign up for updates below. Or if you're already sold on the idea, please let us know by reserving your toaster for £5. We’re glad for you to be on this next phase of the journey with us!